I have been guilty of this myself. Wake up on a brew day, throw on a brewery-branded Dickie’s work shirt, and commence a five hour brew day or eight hour double brew day. As I have embarked on my journey as a brewer I have adapted practices and applied theories developed in professional brewing in my own brewing.

Now there is equipment made for homebrewers that is basically scaled down versions of professional equipment. There are turnkey brewing systems with pumps, controllers and chillers that wouldn’t look out of place at a nanobrewery. Homebrewers can turn their basements into forests of stainless steel conicals. If you have enough stainless fermenters it only makes sense to hook your fermenters up to a glycol chiller. And to cosplay for your family and friends who may not visit your home brewery, more brewers are buying a can seamer to you can hand out cans of homebrew just like more and more commercial breweries are doing.

There is nothing wrong with any of the above by the way. We all do it for the same reasons: brew better beer! Over the years the quality and consistency of my beer has improved. That is not to say all of the above is necessary to brew great beer and improve as a brewer.

In college my major was sport management. In a sports marketing class one of the concepts discussed was a ladder of fandom. On the bottom wrung might be the person who isn’t a fan of the team or property you are marketing, but might go to an game or event socially. The next step up might be the casual fan who goes to a couple of game a year and watches once in awhile on TV. The idea is the higher up on the ladder, the more loyal and attached that fan is.

Let’s apply that ladder concept to homebrewing. On the bottom rung is probably a beer drinker that is intrigued by the idea of making their own beer. The next step is would be the kit brewer that makes beer kits made with hopped malt extract. When I started brewing I started on the second rung, brewing with un-hopped malt extract and steeped specialty grains. Staying with the concept, the next rung would be extract brewing with a full boil which typically requires a separate burner and wort chiller. Next would be partial mash, then all-grain at the top. The way the hobby has evolved more and more brewers are starting with all-grain brewing, or at least racing to the top of the ladder as fast as they can.

In sports marketing as fans climb the ladder they become more engaged with a team or sport. With homebrewing that distinction isn’t as clear. The homebrewer that climbs the ladder certainly gains knowledge about the brewing process. Armed with the right information they have more control over the beer that they brew. My question is does a longer, more complicated, and often more expensive process make these brewers more engaged?

In a lot of cases the answer is yes. I know plenty of brewers that are brewing new beers all the time. When I see them post on social media they have a new piece of gear in their home brewery. On the flip side, I know plenty of brewers that climbed the ladder, then things changed in their lives like work and family commitments. For them it became more difficult to make time for the five hour plus brew day, or spend money on more shiny equipment.

The innovations that homebrewing has seen in just the seven years I have been brewing have been tremendous. A lot of the high-end equipment I mentioned didn’t exist back then. It does seem to me a lot of the innovation has been geared toward the brewers at the top of the ladder. Innovations geared toward the new brewer like PicoBrew, or new LG system do come with a higher price tag that may be more of a barrier to entry than the $100 starter kit you find at the homebrew shop.

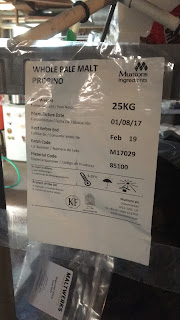

Participation in homebrewing peaked in the early part of the decade and has been slowly declining ever since. Homebrewing is a hobby, and hobbies will naturally have peaks and troughs. In my role with Muntons I do speak with both online and brick and mortar retailers from time to time. People in the industry that I talk to are trying to find ways to get new people into the hobby, and keep more people engaged in the hobby. We as a community and as an industry need to embrace ways to keep the barrier to entry low, and make homebrewing easier for everyone to keep brewers involved.

It’s not good for anyone if a person who is interested in making their own beer looks at what is involved in brewing and decides it’s too much work, too complicated, or too expensive. You can make great beer in 15 minutes with a hopped extract kit. Anyone has time to do that! I couldn’t be happier with how my Rundown Irish Red came out. I made that beer with extract and steeped specialty grains, the same process as my first ever batch.

|

| I made an awesome batch the old-fashioned way! |

I once described homebrewing to someone as like making pasta sauce. Extract brewing was like making your sauce with canned tomatoes, then adding your own spices and seasonings, while all-grain brewing was more like making sauce with all fresh tomatoes and vegetables. I don’t know anyone who turns their nose up at a homemade Italian dinner because the tomatoes came out of a can.

I don’t want to sound like I am schilling for beer kits and extract brewing because I work for a beer kit and malt extract manufacturer. Those are just two examples of how you can make great beer at home without playing pro-brewer. I’ve brewed award-winning beers using a brew-in-a-bag all grain and partial mash method. To date my only first place winner was a lager I brewed on my stove-top, and fermented at room temperature. About as easy and low-tech as all-grain brewing can get!

Denny Conn and Brew Beechum are releasing a book entitled Simple Homebrewing. I pre-ordered my copy and look forward to reading it. I think this is an important book and hope it starts a conversation in the community.

Homebrewing doesn’t have to be as complex as commercial brewing, and that’s a good thing! It is easy to forget how simple it can be to make great beer. One of the early credos of this space was the homebrewing can be as involved of a hobby as you want it to be. If the hobby becomes so involving that it eats itself that’s not good for anyone.

Like The Would-be Brewmaster on Facebook

from Blogger http://bit.ly/2LxCjjJ

via IFTTT